ABOVE: © iStock.com, Alfadanz

Imagine a bandage that could weave a wound back together near-instantaneously. Or a filter for cleaning toxic spills that could sense and adapt to its environment. These are just some of the applications that may be possible for materials built from living cells.

Engineered living materials (ELMs) can theoretically take on the properties of tissue, meaning they can grow and self-propagate. Previously, scientists have succeeded in engineering cells to come together into moldable materials, but it’s been challenging to precisely control and shape how they assemble without chemical modifications that may harm the cells.

While scientists been able to shape ELMs made of bacterial cells by sculpting biofilm-building proteins, directing eukaryotic cells to where they’re supposed to go has been more challenging. In a study published in Science Advances on November 4, scientists directed genetically engineered baker’s yeast (Saccharomyces cerevisiae) to assemble into ELMs. With the help of microscopic “tweezers,” they were able to precisely control the shape and size of the resulting ELM without chemical modifications.

“It’s really difficult to introduce biological functions into materials,” says Sara Molinari, a synthetic biologist at Rice University who was not involved in the study. Nevertheless, it was a goal worth pursuing because “yeast are better for certain applications,” Molinari explains.

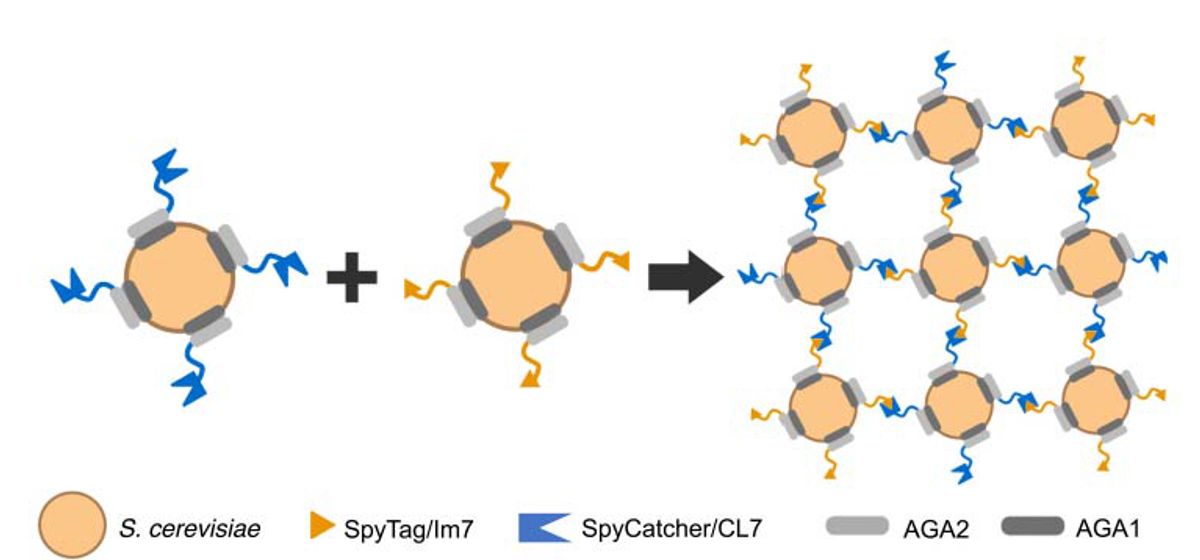

To try and glue eukaryotic cells together, the authors made use of what are known as ultrahigh-affinity protein-protein interactions (PPIs) among four synthetic proteins previously derived from bacteria. These interactions, as their name suggests, cause proteins to clamp onto each other extremely tightly. The proteins come in pairs that form strong PPI bonds with one another, like a lock and key: SpyTag and SpyCatcher, and Im7 and CL7. The researchers also took advantage of yeast’s natural tendency to form colonies via weak interactions.

The team cloned genes encoding SpyTag, SpyCatcher, Im7, and CL7 into yeast, which then began to express these proteins on their extracellular membranes. Then, the researchers used optical tweezers—a noninvasive technique that uses lasers to manipulate living cells—to bring individual yeast cells containing complementary PPI-forming proteins together and to break other cells apart. These tweezers allowed researchers to measure the strength of interactions among the cells while both controlling and assessing the nature of the assembly of living cells at the microscopic level.

“One thing I’ve never seen before is using optical tweezers to trap single cells. I thought that was really cool,” says Molinari.

After an ultra-strong PPI is formed between two yeast cells, the cells continue dividing, forming more ultra-strong bonds with their daughter cells.

This technique could be used to produce self-propagating ELMs that have useful functions, such extracting uranium from seawater, which could be used as a renewable source of nuclear power, according to the paper. The researchers engineered production of a uranium-sequestering protein in the yeast and found that the material continued to grow and produce more of the protein. “There is a huge uranium reserve in the oceans,” writes Fei Sun, a chemist and biological engineer at the Hong Kong Science and Technology University, in an email to The Scientist. “Self-growing ELMs, with their abilities to produce efficient uranium-binding ligands, may provide cost-effective solutions to the challenges facing chemical separation and energy industries.” Sun led the study along with colleagues Richard Lakerveld, a chemical engineer, and Jinqing Huang, a biophysican chemist.

The researchers also successfully cloned a sticky, water-resistant molecule derived from the marine blue mussel (Mytilus edulis) into a separate batch of yeast that also contained SpyTag and SpyCatcher. These cells effectively glued themselves to a variety of things, including skin and glass. “The resulting ELMs turned out to be extremely effective bioglues” that could be used for wound healing, says Sun.

“Engineered living materials . . . [have] the promise to revolutionize the field of materials,” and new applications such as the ones described in this study are “encouraging,” Molinari says. However, she points out that the ELMs assembled using this method are still less than 20 microns in diameter, and there’s likely further research that needs to be done before yeast can be formed into large, macro-scale ELMs.

“Overall, the ability to functionalize individual cells with genetic engineering and precisely assemble them into structured materials with microfluidics and optical tweezers provides a rich platform for new classes of advanced materials,” Sun says. “This is unprecedented and transforming.”